AS9100D & ISO 9001:2015 CERTIFIED

CNC Equipment

Okuma MB 5000H

Okuma Genos M460V-5 AX

YCM TCV 3000A-5 AX

Horizontal machining center with pallet changer. X, Y, & Z 29.92". Full 4th axis, 15,000 RPM spindle, and 1,000 PSI thru coolant.

YCM TCV 3000A-5 AX

Okuma Genos M460V-5 AX

YCM TCV 3000A-5 AX

Full 5 axis vertical machining center equipped with 110 deg swivel milling head and 360 deg integrated rotary table. X, Y & Z travel 118" x 31.5" x 31.5". 12,000 rpm spindle and 1,000 PSI thru coolant. Laser aligned.

Okuma Genos M460V-5 AX

Okuma Genos M460V-5 AX

Okuma Genos M460V-5 AX

Full 5 axis machining center. X, Y & Z travel 30" x 18.11" x 18.11". A axis +20 deg ~ -110 deg, C axis 360 deg. 15,000 rpm spindle and 1,000 PSI thru coolant.

(4) YCM XV 1020A

Okuma multi axis Genos L300 Bar Feeder

Okuma Genos M460V-5 AX

We have 4 of the YCM XV 1020A vertical mills. X axis 40", Y axis 20.4", Z axis 21.2". 10,000 RPM spindle, thru coolant.

Okuma multi axis Genos L300 Bar Feeder

Okuma multi axis Genos L300 Bar Feeder

Okuma multi axis Genos L300 Bar Feeder

Bar feeder lathe with sub spindle and parts catcher. Live tooling, programmable tail stock. 10" chuck with full 4th axis milling capability with X, Y, Z, and C axis.

Twinhorn VA 500

Okuma multi axis Genos L300 Bar Feeder

Okuma multi axis Genos L300 Bar Feeder

We have 2 of the Twinhorn VA 500 vertical mills. X axis 16.68", Y axis 15.75", Z axis 17.71". 8,000 RPM spindle.

(2) Hardinge Bridgeport GX 480

(2) Hardinge Bridgeport GX 480

(2) Hardinge Bridgeport GX 480

We have 2 Bridgeport GX 480 with pallet changer. X 18.9", Y 15.75", Z 16.93". 10,000 RPM spindle with thru coolant.

Jyoti 850-DM NVU

(2) Hardinge Bridgeport GX 480

(2) Hardinge Bridgeport GX 480

Vertical machining center with. X 32.284", Y 20.079", Z 20.079". 10,000 RPM spindle.

Okuma LB3000 EX 2

Okuma LB3000 EX 2

Okuma LB3000 EX 2

OSP P300L control. 10" chuck and programmable tail stock. Thru coolant capable, 12 tool turret.

Okuma LB3000 EX

Okuma LB3000 EX 2

Okuma LB3000 EX 2

OSP P200L control. Y axis, live tooling (X axis, rotary head Z). Parts catcher, 10" chuck, and programmable tail stock. Thru coolant capable, 12 tool turret.

Hwacheon Cutex 180B

Oi-TF fanuc control. 6" chuck, max spindle speed 4,500 RPM, 12 tool turret, and parts catcher.

CMM

Hexagon Metrology 7.10.7 SF

Hexagon Metrology 7.10.7 SF shop floor coordinate measuring machine. It is designed from the ground up to surpass the demanding requirements of a shop floor. We have also added the the tesastar-m, TKJ 7.5 degree head which allows us to inspect even the most complex parts.

Manual Machining

Manual Grinding

2 - O.D. grinders

2 - I.D. grinders

2 - 6 x 18 surface grinders

Manual Machining

1 - Acer knee mill

1 - Lathe

2 - Saws

1 - Sunnen hone

3 - Drill presses

1 - 20 ton hydralic press

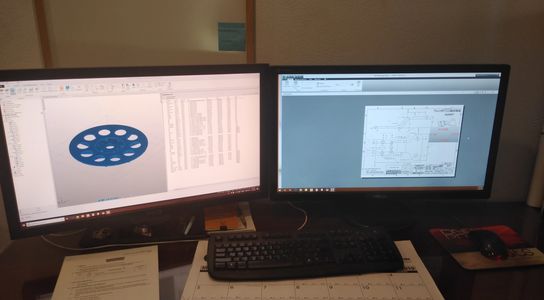

Cad/Cam technologies

FeatureCAM

A state of the art CAD/CAM center powered by FeatureCAM provides all the CNC equipment with the code necessary to process the most complex shapes. We currently have five programming stations. Capable of programming 4th and 5th axis. Send us your model or print and we will take it from there.